All-plastic parts

Plastic – in the widest variety of chemical compositions – reinforced or without reinforcement.

Composite parts

Metal parts can be manually, completely or semi-automatically placed in injection moulding tools and insert moulded or back-injected.

Four companies

fourfold competence

All-plastic parts, micro parts

composite parts & assembly partsMould production

for injection moulding toolsSteel processing

State-of-the-art injection moulding production

Product development for the customer

Warehousing & just-in-time delivery

UPSTREAM AND DOWN-STREAM PRODUCTION

As your partner, we offer more than just production.

Development and prototypes of your ideas

We produce plastic products economically in our factory with complex geometry and in a short period of time.

Our services for you:

• Support

• Feasibility analysis

• 3D construction

• Prototype builds

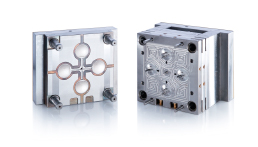

Tool manufacturing all in one place

Injection moulding requires tools. Our affiliated mould production allows us to flexibly and precisely realise the product developed together with you.

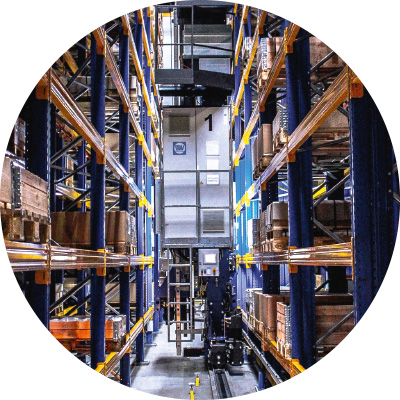

Temporary storage and just-in-time delivery

Our state-of-the-art warehouse system makes intelligent use of space. For smaller operations, outsourcing means transforming previous warehouse space into new production space. For larger operations, we produce in economic quantities and deliver directly and reliably to production, just-in-time.

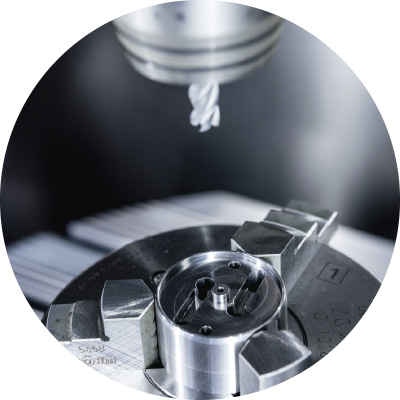

INJECTION MOULDING MACHINES

We manufacture using the latest fully-electronic injection moulding machines.

In this fully-automated way, we keep lean manufacturing in sight. We guarantee 24-hour deliveries with a 3-stage operation. Single and multi-component combinations ranging from 0.009 to 1000 grams for all regional and nationwide branches.

• Fully-automated injection moulding machines with extraction

• Injection weight 0.009 to 1000 g

• Single and multi-component combinations

• Fully-automated raw material drying and supply

• Closed cooling system